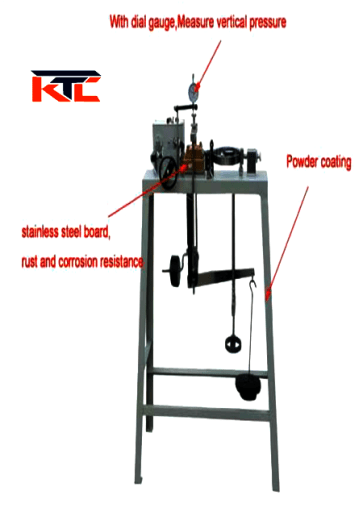

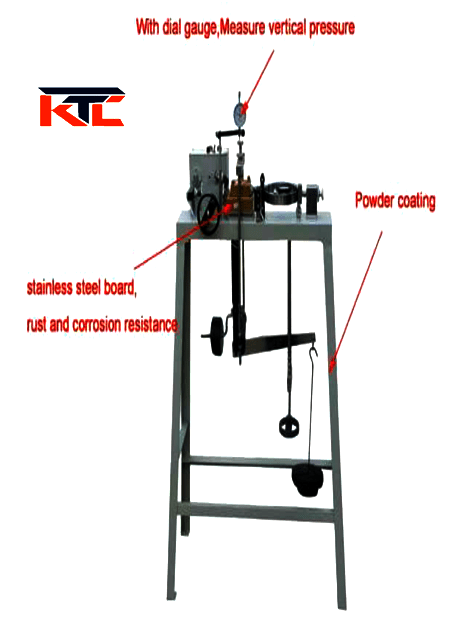

Direct Shear Apparatus

Best Direct Shear Apparatus is a common laboratory testing device used in geotechnical engineering to determine the shear strength parameters of soil..

Direct Shear Apparatus: best direct shear apparatus

The Direct Shear Apparatus is a common laboratory testing device used in geotechnical engineering to determine the shear strength parameters of soil, primarily cohesion (c) and the angle of internal friction (ϕ). These parameters are crucial for designing various civil engineering structures like foundations, retaining walls, and for analyzing slope stability.

Description of the Direct Shear Apparatus:

The apparatus works on the principle of shearing a soil specimen along a predetermined horizontal plane. Here’s a breakdown of its main components and how it works

- Shear Box: This is the core of the apparatus. It’s typically a square or cylindrical box divided horizontally into two halves. The soil specimen is placed within this box. The upper half is designed to move horizontally relative to the lower half.

- Handwheel speed: 0.1, 4, 12mm/min7. AC220VAC 60HZ8.Packing measurement for EDJ-1: 880x600x1210mm, weight: 105kg.

-

Handwheel speed: 0.1, 4, 12mm/min7. AC220VAC 60HZ8.Packing measurement for EDJ-1: 880x600x1210mm, weight: 105kg.

| Specification | Direct Shear Apparatus | Application: This apparatus is used to test resisting shear strength of soil specimen. Specification: |

| 1. Area of the soil sample:30cm 2. Lever ratio: 1:12 3. Vertical loading: 50,100,200,300,400(Kpa) 4. Max. horizontal loading: 1.2KN 5. Shear rate: 0.02, 0.8, 2.4mm/min |

6. Handwheel speed: 0.1, 4, 12mm/min 7. AC220VAC 60HZ 8.Packing measurement for EDJ-1: 880x600x1210mm, weight: 105kg |

- Porous Stones: Placed at the top and bottom of the soil specimen within the shear box. These allow for drainage of water from the soil during the test, especially for consolidated-drained conditions.

- Grid Plates: Sometimes used in conjunction with porous stones, especially for granular soils, to provide better grip and prevent squeezing out of the soil.

2 .Loading Unit/Frame: This unit applies both normal (vertical) and shear (horizontal) loads to the specimen.

- Normal Load Application: A vertical load is applied to the top of the specimen, simulating the overburden pressure or weight of structures above the soil. This can be achieved using dead weights and a lever system, or more modern apparatus may use pneumatic or motorized systems.

- Shear Load Application: A horizontal force is applied to one half of the shear box, causing the soil specimen to shear along the plane separating the two halves. This is typically done at a constant rate of strain using a motor-driven mechanism.

3.Measurement Devices:

Load Cells/Proving Rings: These are used to measure the horizontal shear force applied to the specimen and the vertical normal load. In older systems, proving rings with dial gauges were common, while newer, digital systems use load cells that provide electronic readings.

Displacement Transducers/Dial Gauges:

- Horizontal Displacement (Shear Displacement) Gauge: Measures the horizontal movement of the upper shear box relative to the lower one.

Vertical Displacement (Consolidation/Dilation) Gauge: Measures the change in height of the specimen, indicating consolidation (settlement) or dilation (expansion) during the application of normal load and shearing.

How the Test is Performed (Simplified Procedure):

- A soil specimen (undisturbed or remolded) is carefully prepared and placed into the shear box.

- The shear box halves are clamped together, and porous stones and grid plates (if used) are placed on top and bottom of the specimen.

- The entire assembly is placed in the loading unit.

- A predetermined normal load is applied vertically to the specimen.

- After allowing for consolidation (if required, for drained conditions), the clamping screws are removed, creating a small gap between the two halves of the shear box.

- A horizontal shear force is then gradually applied at a constant rate, causing the specimen to shear along the horizontal plane.

- Readings of shear force, horizontal displacement, and sometimes vertical displacement are recorded at regular intervals until the specimen fails or a specified displacement is reached.

Advantages and Limitations:

Advantages of Best Direct Shear Apparatus:

- Relatively simple and inexpensive equipment.

- Easy to perform and interpret results for granular soils.

- Can be used to test various soil types under different conditions

Limitations:

- The failure plane is forced along a predetermined horizontal plane, which may not be the weakest plane in the soil.

- Pore water pressure cannot be easily measured during the test, making it less suitable for undrained conditions in cohesive soils compared to the triaxial test.

- Stress distribution within the sample is not uniform, especially at the edges.

Be the first to review “Direct Shear Apparatus”

You must be logged in to post a review.

Reviews

There are no reviews yet.