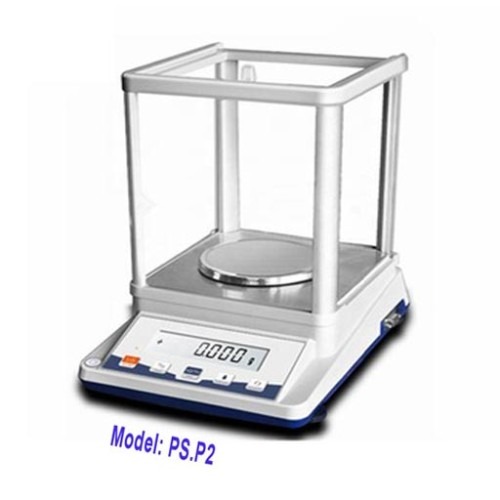

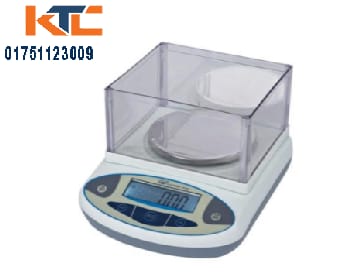

Digital Precision Digital Balance

৳ 9,000.00

The Digital Precision Digital Balance is a highly accurate instrument used to measure (.01gm-600gm) the mass of objects.

Digital Precision Digital Balance:

The Digital Precision Digital Balance (often simply called a precision balance or electronic balance) is a highly accurate instrument used to measure the mass of objects. Unlike older mechanical scales that rely on levers and counterweights, digital balances utilize electronic sensors and microprocessing technology to provide quick, precise, and easily readable measurements on a digital display.

They are widely used in various fields where accurate weight measurements are crucial, such as:

- Laboratories: For scientific experiments, preparing solutions, and measuring chemicals.

- Manufacturing: For quality control, batch weighing, and process monitoring.

- Pharmaceutical Industry: For precise ingredient measurement in drug production.

How a Digital Precision Digital Balance Works:

Most modern digital balances, especially precision and analytical balances, operate on the principle of Electromagnetic Force Restoration (EMFR) or Load Cell Technology. Here’s a simplified explanation:

- Load Cell (or Weighing Sensor): This is the core component. When an object is placed on the weighing pan, it exerts a downward force due to gravity.

- EMFR (Electromagnetic Force Restoration): In this type, the weighing pan is connected to an electromagnetic coil that floats in a magnetic field. When a load is placed on the pan, it causes a slight downward displacement of the coil. A position detector senses this displacement, and an electronic circuit (often with a PID regulator) then precisely increases the current flowing through the coil. This increased current generates an upward electromagnetic force that counteracts the downward force of the object, restoring the pan to its original equilibrium position. The amount of current required to achieve this balance is directly proportional to the object’s mass.

- Strain Gauge Load Cell: In this type, the load cell contains strain gauges (thin electrical conductors attached to a flexible material). When weight is applied, the material deforms slightly, causing the strain gauges to stretch or compress. This deformation changes their electrical resistance.

Signal Conversion:

- For EMFR balances, the change in current is measured.

- Microprocessor: The A/D converter transforms the analog signal into a digital signal. A built-in microprocessor then processes this digital signal, applies calibration data, and converts it into a mass value (e.g., grams, milligrams, kilograms).

Digital Display: The calculated mass value is then shown on a digital display, providing an accurate and easy-to-read result.

Key Features and Functions of Digital Precision Digital Balance:

- High Precision and Accuracy: Designed to measure even very small masses with high reliability.

- Digital Readout: Provides clear and unambiguous results.

- Tare Function: Allows the user to zero out the weight of a container, so only the weight of the contents is measured. This is incredibly useful in laboratories for weighing powders or liquids in beakers.

- Calibration: Digital balances require regular calibration to maintain their accuracy. Many have internal automatic calibration or can be calibrated using external test weights.

- Multiple Units: Can often measure in various units (g, mg, kg, oz, lb, etc.).

- Stability: Designed to return to their initial equilibrium quickly and maintain stable readings.

- Draft Shield (for analytical balances): Highly sensitive balances often have a glass enclosure to protect the weighing pan from air currents and other environmental disturbances that could affect the reading. Another web site and our web site is same to machine.

- In summary, a digital precision balance is a sophisticated electronic tool that translates the force exerted by an object’s mass into a precise digital reading, making it indispensable for accurate weighing in a multitude of applications. Thanks all.

| .01gm-600gm | Measurements |

|---|

Be the first to review “Digital Precision Digital Balance”

You must be logged in to post a review.

Reviews

There are no reviews yet.